Scope of the project: to increase the production capacity and quality of products according to integrated expansion in MSC

Client: Mobarakeh Steel Company

Contract amount: Euro 19,7 million

Project completion: 2002

Scope of the project: production and treatment of 4.2 million tons of liquid steel per year in MSC melt shop

Client: Mobarakeh Steel Company

Contract amount: Euro 19,2 million

Project completion: 2001

Scope of the project: to increase the capacity of reheating furnace in hot rolling mill to more than 4.5 million tons slabs

Client: Mobarakeh Steel Company

Contract amount: Euro 9,5 million

Project completion: 2002

Scope of the project: to increase the production capacity and quality of products according to integrated expansion in MSC

Client: Mobarakeh Steel Company

Contract amount: Euro 19,7 million

Project completion: 2002

Scope of the project: to increase the number of reheating furnaces of slab to increase the capacity of hot rolling mill.

Client: Mobarakeh Steel Company

Contract amount: Euro 6,1 million

Project completion: 2002

Scope of the project: to increase the production of hot rolling mill according to RFP and ladle furnaces

Client: Mobarakeh Steel Company

Contract amount: Euro 24,8 million

Project completion: 2002

Scope of the project: to increase the production capacity to 4.2 million tons liquid steel and 3.95 million tons slab

Client: Mobarakeh Steel Company

Contract amount: Euro 29,7 million

Initial Date:: January 2002

Project completion: 2006

Scope of the project: supply of Steel Making Plant (“SMP”) for production of 1.5 million tons per year of slabs with steel grade of low medium and high carbon.

Irasco scope was to supply first fill of 6 months consumables, spare parts for two years, bulk material and mobile equipment.

Client: Iranian Mines and Mining Industries Development and Renovation Organization IMIDRO

Contract amount:Euro 15.4 million

Initial date: February 2006

Project completion: June 2011

Scope of the project: realization of a Midrex Direct Reduction process plant with annual capacity of 800,000 tons of DRI in Neyshabour – Iran

Client: International Metals Production and Development Company (IMPADCO)

Contract amount: Euro 65 million

Initial date: January 2007

Project completion: November 2010

Scope of the project: realization of a 600 series Midrex Direct Reduction process plant for Iranian Ghadir Steel Company for production of 800,000 tons per year of DRI in Adakan-IRAN using natural gas and recycling it.This process has low energy consumption and low environmental impact, making it an environmental friendly process.

Client: Ghadir Iron & Steel Company IGISCO

Contract amount: Euro 70 million

Initial date: May 2007

Project completion: 2014

Scope of the project: direct reduction Plant for Arfa Iron and Steel Company (AISCO) for production of 800,000 tons per year of DRI in Adakan-IRAN using natural gas recycling it. This process has low energy consumption and low environmental impact, making it an environmental friendly process

Client: Arfa Iron and Steel Company AISCO

Contract amount: Euro 58.3

Initial date: July 2008

The commissioning started in November 2013

Scope of the project: two mega modules direct reduction plants for the total production of 3 million tons per year of DRI by Midrex DR process using natural gas

Client: Mobarakeh Steel Company

Contract amount: Euro 58.8 million

Initial date: March 2008

Project completion: 2018

Scope of the project: consisting of a 600 series a Midrex module with all utilities and auxiliary sistems with Technical Specification under the Contract to produce 800.000 ton per year of Direct Reduced Iron in Neishabour, Iran

Client: Khorasan Steel Complex (KSC)

Contract amount: Euro 33.2 million

Initial date: November 2006

Project completion: 2017

Scope of the project: production of 1.8 million tons of semi-finished products per year consisting of billets through an expansion of the plant located at Neishabour, Iran.

Client: Khorasan Steel Company

Contract amount: Euro 55.3 million

Initial date: April 2008

Project in progress

Scope of the project: realization of a 600 series Midrex Direct Reduction process plant to produce 800.000 of DRI per year

Client: National Iranian Steel Company NISCO

Contract amount: Euro 20 million

Initial date: June 2008

Project in progress

Steel Making Plant

Scope of the project: to establish a steel making plant to produce 800.000 tons of billets and blooms per year

Client: National Iranian Steel Company NISCO

Contract amount: Euro 12,5 million

Initial date: November 2008

Project in progress

Scope of the project: revamping steel making to increase MSC production from 2.4 to 4.2 million tons/year, upgrading the quality of products and reducing the cost of production

Client: Iritec/Mobarakeh Steel Company

Contract amount:Euro 8,7 million from Iritec, 40 million from MSC

Initial date: August 2008

Project completion: October 2010

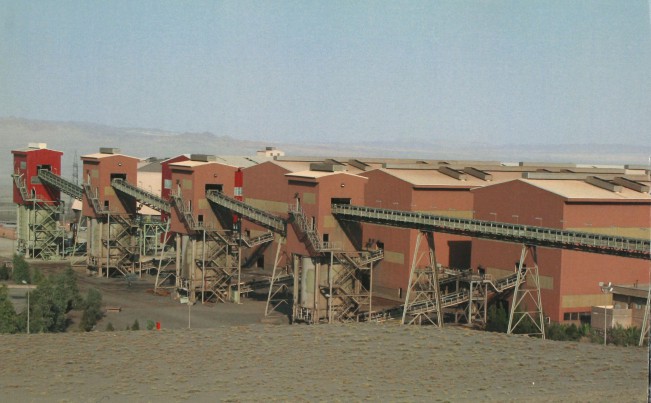

Tabas Coal Mines are located 85 Kilometers south of the provincial town of Tabas in an area of 1200 square Kilometers.

Scope of the project: to establish the first mechanized coal mining in Iran designed for an ultimate run of mine capacity of 1.5 million tons and washed coal of 750,000 tons/year and enhance safety aspects of mining industry by respecting the European safety standards.

Client: National Iranian Steel Company NISCO

Contract amount: USD 153 million

Initial date: August 2001

Project completion: 2009

Scope of the project: to increase the copper production of the Sarcheshmeh Copper Mine and reach the production of 160.000 dry metric tons per year of Copper Concentrate.

Client: National Iranian Copper Industries Company NICICO

Contract amount: Euro 45,8 million

Date of signature: March 2009

Initial date: 2010

The commissioning started in December 2016

Scope of the project: to increase the capacity of existing plant for Iron Ore Dressing into a capacity of 1.7 million tons per year

Client: Chadormalu Mining and Industrial Company CMCI

Contract amount: Euro 38.5 + 7.33 million

Initial date: July 2008

Project completion: 2016

Scope of the project: the engineering, procurement construction and commissioning of seven gas compression stations, a gas treatment plant, 280 Km of gas pipe line and about 100 Km of power transmission lines, in Ahwaz, Mansouri, Ab-Teymour, Kupal e Marun areas in south west of IRAN. The purpose was to stop flaring of 6.8 million cubic meters of associated gases per day and to stop emission of 18,000 tons of pollutant per day.

Client: National Iranian Oil Company NIOC – PEDEC

Contract amount: 228.3 million USD

Initial date: April 2000

Project completion: 2007

Scope of the project: to install new onshore facilities at Kharg Island, in the Persian Gulf, including reception facilities for receiving offshore gases from onshore fields, onshore compression stations, NGL trains, processing facilities for the production of residue gas, ethane vapor, protect the environment from high amount of emission caused by the flaring of gases in the region

Client: Iranian Offshore Oil Company IOOC

Contract amount: Euro 179 million

Initial date: September 2006

Project in progress

Scope of the project: supply of a plant for desalination of 50.000 barrels per day of crude oil.

Client: National Iranian South Oil Company NISOC

Contract amount: Euro 5,4 million

Initial date: January 2006

Project completion: January 2012

COPYRIGHT 2023 IRASCO S.r.l. | P.IVA: IT03465490104 | Privacy Policy